Complete Engine Analysis: From Operation to Construction Diagrams

This article, though not in-depth, aims to initially reveal the mysteries of the engine and serve as a useful reference for choosing a motorcycle. The motorcycle engine, the central component of the vehicle, provides the necessary propulsion for movement, allowing riders to enjoy the freedom and adrenaline of riding. However, it's unfortunate that the information about engines available online is often incomplete or difficult to understand. After careful research and organization, I've finally managed to more clearly interpret the fundamental parameters of motorcycles and explain the engine's operating principle in simple terms. To share this knowledge more widely, I've decided to organize my understanding into an article for the benefit of readers. In describing it, I've tried to avoid complex technical terms, striving to present the mysteries of the engine in an accessible manner. If you notice any errors or omissions while reading, please let me know in the comments; I'll correct them as soon as possible.

A. Demonstration of the Engine Working Process

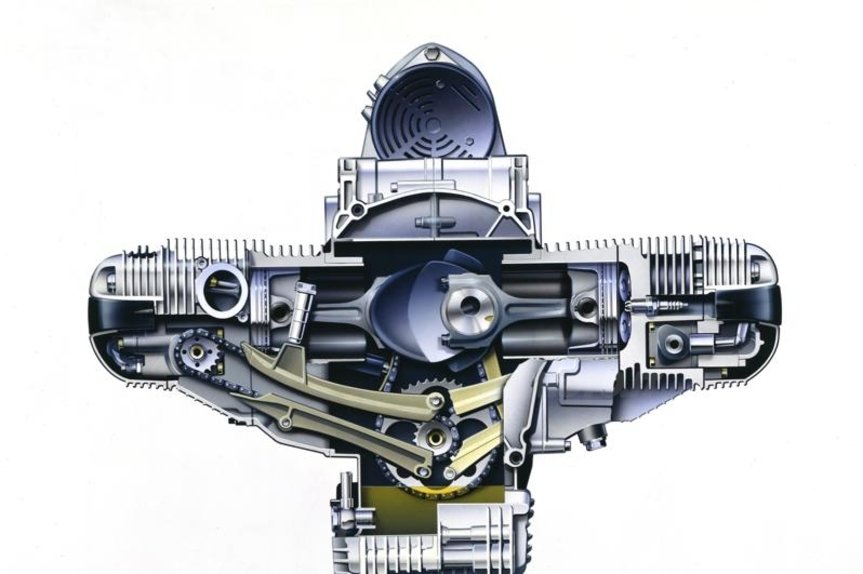

Next, we take a detailed look at the working process of a Ducati twin-cylinder four-stroke engine through a video.

This engine, appreciated for its exceptional performance and stable operation, has won over many motorcycle enthusiasts.

Through the video, you can clearly see the coordinated work of the various engine components and feel the power it gives to the motorcycle.

B. Classification of Engines

An engine, also known as a propeller, is a device capable of converting various forms of energy into mechanical energy. There are many types, including internal combustion engines, electric motors, steam engines, turbines, and windmills. Among these, heat engines and electric motors are two common types. Heat engines primarily convert thermal energy (from gasoline, diesel, etc.) into kinetic energy, while electric motors convert electrical energy into kinetic energy. Currently, heat engines, which burn gasoline to propel the motorcycle forward, are widely used in the motorcycle market.

The engines used in motorcycles are primarily internal combustion engines. Their operating principle is based on generating power through the expansion of fuel combustion in a confined space. Specifically, the fuel-air mixture (with the addition of a small amount of oil in two-stroke engines to lubricate the piston) is ignited by the spark plug; the heat generated by combustion causes the gases to expand. This expansion force is ultimately converted into mechanical energy and released as power via a mechanical device (such as a reciprocating engine).

The reciprocating engine is the most common form of internal combustion engine. In it, combustion gases push the piston in a reciprocating motion (up and down); the piston then transmits this alternating linear motion to the crankshaft, which converts it into rotary motion, thus providing power to the motorcycle.

C. Detailed Analysis of Engine Construction and Glossary of Terms

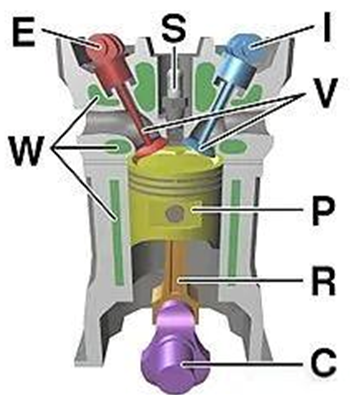

Let's now delve deeper into the internal construction of the engine. Taking a four-stroke engine as an example, its operating principle and the names of its components are illustrated in the figure.

By understanding these construction details, we can more fully understand how the engine efficiently converts heat into motion.

1. E: Exhaust camshaft

2. I: Intake camshaft

3. S: Spark plug

The spark plug is responsible for generating the electric spark that ignites the compressed, atomized mixture of gasoline and air.

4. V: Valve

The valve controls the entry of the air-fuel mixture into the combustion chamber and the expulsion of exhaust gases after combustion.

5. P: Piston

The piston is called the "central component" of the engine.

It is responsible for converting the combustion energy in the cylinder into mechanical energy and transmitting the power to the crankshaft via the connecting rod.

It also performs the crucial task of withstanding the high-temperature, high-pressure combustion environment and, together with the cylinder head and cylinder walls, forms the combustion chamber.

Its upper part is usually equipped with two sealing rings (oil rings) and an oil scraper ring (oil scraper ring) to prevent fresh mixture and exhaust gases from entering the crankcase and to prevent crankcase oil from entering the combustion chamber.

6. R: Engine connecting rod

The connecting rod, a key power transmission device, is responsible for transmitting the force generated by the piston to the crankshaft, thus driving the entire engine system.

7. C: Crankshaft

The crankshaft, this long rotating shaft, is an indispensable component. It skillfully converts the kinetic energy of the reciprocating linear motion of the piston into rotational kinetic energy, driving the normal operation of the engine system. However, during operation, the crankshaft is subject to significant friction, causing wear. For this reason, designers have specifically created oil holes on the surface of the crankshaft to ensure that oil lubricates every corner, effectively reducing frictional losses and extending the life of the crankshaft.

8. W: Water jacket (for liquid cooling)

The water jacket, an important component of the engine cooling system, cools the combustion chamber at high temperatures, preventing damage to the engine's lifespan from continuous heat. Thanks to the water jacket's cooling, the engine can maintain a suitable operating temperature, ensuring long-term stable operation.

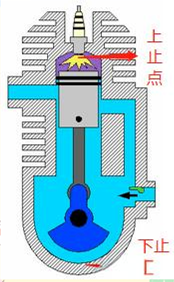

9. Stroke

Stroke, a key indicator of an engine's operating cycle, encompasses the entire process in which the piston moves from top dead center (TDC) to bottom dead center (BDC) and back to TDC. It describes a complete operating cycle, which includes the four fundamental phases: intake, compression, combustion (expansion), and exhaust. In two-stroke engines, for each complete revolution of the crankshaft, the piston completes a movement from TDC to BDC and back to TDC, thus constituting a complete stroke.

The workflow of a four-stroke engine is different. In a four-stroke engine, completing a work cycle requires two full revolutions of the crankshaft, during which the piston contacts TDC and BDC twice each. This process still includes the four key phases of intake, compression, combustion, and exhaust, but is more complex than that of a two-stroke engine.

10. Displacement

Displacement is determined by the size (volume) of the cylinder. A larger displacement means more air-fuel mixture can be drawn in, thus releasing greater explosive energy per cycle. It is calculated using the formula: (Cylinder Radius)² x π (Pi) x Stroke x Number of Cylinders. Taking a four-cylinder engine with an 80 mm bore and 90 mm stroke as an example, we can calculate its displacement:

(40)² (radius squared) x 3.14 (π) x 90 (stroke) x 4 (number of cylinders) = 1.8 liters. Since the cylinder cross-section is circular and π is an irrational number, it is impossible to obtain an integer result in the actual calculation. Therefore, the declared displacement for motorcycles is often slightly higher than the actual displacement. For example, if declared as 150 ml, the actual displacement might be 149 ml.

11. Stroke

Stroke, or the distance the piston travels from TDC to BDC, is an important engine parameter. Stroke length directly affects engine performance. A longer stroke increases the piston's reciprocating distance and also increases the connecting rod's amplitude. This increases the crankshaft's length, thereby increasing the engine's torque output but reducing maximum rpm. Therefore, long-stroke engines are better suited to operating in environments with low speed requirements and rough road conditions, such as those used in dirt bikes. Conversely, short-stroke engines are more geared towards high rpm and high power.

12. Compression ratio

The compression ratio indicates the degree of compression of the air-fuel mixture. It is calculated as the volume of the combustion chamber divided by the total volume of the cylinder. After the intake stroke, the piston moves upward, compressing the mixture. When the electric spark ignites this compressed mixture, it releases energy, pushing the piston downward, thus generating power. A higher compression ratio increases the engine's power output. However, the compression ratio cannot be increased indefinitely. Too high a ratio can cause detonation (knocking) during the combustion of the mixture, compromising the motorcycle's riding performance and reducing comfort.

13. Engine efficiency

In internal combustion engines, engine efficiency is a key indicator that measures the relationship between input and output. It represents the ratio between the power delivered by the engine and the power generated by fuel combustion. Engine efficiency comprises two key indicators: mechanical efficiency and thermal efficiency.

Mechanical efficiency is defined as the ratio of actual (shaft) power to indicated power. For gasoline engines, mechanical efficiency is generally between 0.8 and 0.9. Thermal efficiency reflects the proportion of the heat generated by fuel combustion that is actually converted into useful work. Compared to the total heat that can be generated, it is an important parameter for measuring engine performance. However, due to losses through the engine cooling system and exhaust gases, only a small portion of the heat generated by fuel combustion can actually be used to perform work. This makes the thermal efficiency of engines relatively low, generally around 20-25%, while automotive engines can achieve efficiencies of 35%.

14. Engine power

The work done by the engine per unit of time is called engine power and reflects the rate at which the engine performs work. Corresponding to indicated work and effective work, engine power can be divided into indicated power and effective power (or shaft power). The difference between these two represents the power lost to mechanical friction. In the International System (SI), the unit of measurement for engine power is the watt (W), but the commonly used unit is the horsepower (hp), where 1 hp = 735 W. It is important to note that increased weight and body thickness for safety reasons can affect the perceived power of the engine. Therefore, motorcycles equipped with small-displacement engines are not always slower or have lower performance than those with more powerful engines.

15. Engine torque

Torque, in physics, is defined as the tendency of a force to rotate an object around an axis or fulcrum. It reflects the torsional effect exerted by the force on the axis or fulcrum. In a motorcycle engine, torque refers to the rotational force transmitted from the crankshaft to the output shaft to drive other components. This force is the fundamental source of the motorcycle's propulsive force: the greater the torque, the greater the motorcycle's tractive force.

16. Carbon deposits in the engine

The accumulation of carbon deposits inside a motorcycle engine can cause a variety of problems, such as valves that don't close properly or that become stuck, leading to reduced engine power, overheating, and increased fuel consumption. Carbon deposits are mainly divided into two categories: oil deposits and carbon deposits. Oil deposits are caused by the decomposition of lubricating oil under high temperatures and pressure. Carbon deposits, on the other hand, result from the incomplete combustion of gasoline, leaving deposits of carbon particles and impurities on many engine parts, such as the combustion chamber surface, piston crown, ring grooves, exhaust ports, and spark plugs.

D. Comparison between Two-Stroke Engine and Four-Stroke Engine

While four-stroke engines dominate the market and are widely used in motorcycles, two-stroke engines have significant advantages in racing. Below, we'll explore in detail the differences between these two engine types and their respective advantages and disadvantages.

1. Operating principle of the two-stroke engine

The working cycle of a two-stroke engine includes two main phases. First phase: Intake and Compression. The piston moves upward, creating a vacuum that draws the mixture of gasoline and air (with a small amount of oil) into the crankcase. Next, the piston moves downward, compressing the fresh mixture in the crankcase. The pre-compressed mixture then flows into the cylinder above the piston. Second phase: Combustion and Exhaust. The mixture above the piston is compressed as the piston rises toward TDC. When the piston is near TDC, the spark plug ignites the mixture. The expansion of the burned gases violently pushes the piston downward (BDC). As it descends, the piston first opens the exhaust port, allowing the burned gases to escape. Next, it opens the transfer (or intake) port, allowing the fresh, pre-compressed mixture in the crankcase to enter the cylinder, also helping to push out residual exhaust gases.

Advantages

At the same rpm, a two-stroke engine has twice the number of combustions as a four-stroke engine, thus delivering greater specific power. Furthermore, the two-stroke engine construction is more compact and lighter, with a significantly reduced number of parts. This gives two-stroke motorcycles a significant performance advantage (power/weight).

Disadvantages

However, two-stroke engines also have drawbacks. Because the intake and exhaust phases occur partially simultaneously and overlap, the exhaust port remains open too long at low rpm. This allows some of the fresh mixture to escape directly through the exhaust along with the burned gases ("fresh charge loss"), reducing power at low rpm. Even more seriously, this unburned fresh mixture is released directly into the atmosphere, causing fuel waste and environmental pollution.

Furthermore, two-stroke engines are subject to faster wear. Due to carbon deposits from the combustion of lubricating oil and the presence of intake and exhaust ports on the cylinder walls, wear is significantly greater than that of four-stroke engines. Typically, a two-stroke engine may need to be replaced after about 10 years, while a four-stroke engine, with proper maintenance, can last over 20 years.

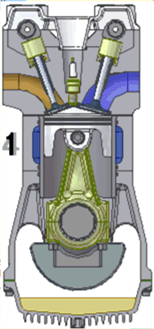

2. Operating principle of the four-stroke engine

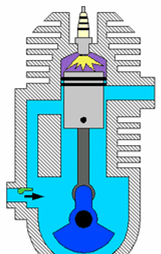

(1) Intake Phase: The piston moves from TDC to BDC. The intake valve opens, allowing the air-fuel mixture to enter the cylinder.

(2) Compression Stroke: The piston moves from BDC to TDC, compressing the air-fuel mixture in the cylinder. Both valves are closed.

(3) Combustion (or Expansion) Phase: When the piston is near TDC at the end of compression, the spark plug ignites the compressed mixture. The rapid expansion of the burnt gases violently pushes the piston from TDC to BDC.

(4) Exhaust Phase: The piston moves from BDC to TDC. The exhaust valve opens, allowing the burnt gases to be expelled from the cylinder.

Advantages

Four-stroke engines offer numerous advantages. First, the intake, compression, expansion (combustion), and exhaust processes are clearly separated and distinct, ensuring stability and high efficiency. This engine can operate over a wide speed range, from low to very high (over 500-1000 rpm). Furthermore, it avoids the problem of fresh charge loss typical of two-stroke engines, thus reducing specific fuel consumption. At low speeds, it runs more smoothly and, thanks to oil lubrication, is less prone to overheating. The intake and compression processes last longer, improving volumetric efficiency and mean effective pressure. Compared to two-stroke engines, thermal loads are lower, reducing the problems of warping and melting. Thanks to their generally longer stroke, they are well-suited for applications requiring high torque.

Disadvantages

However, four-stroke engines also have some disadvantages. The valve train is relatively complex and involves many parts, making maintenance more difficult. Furthermore, this engine tends to generate more mechanical noise during operation. It's important to note that, because the combustion phase (power) occurs only once every two revolutions of the crankshaft, rotation is less balanced than a two-stroke (torsional imbalance).

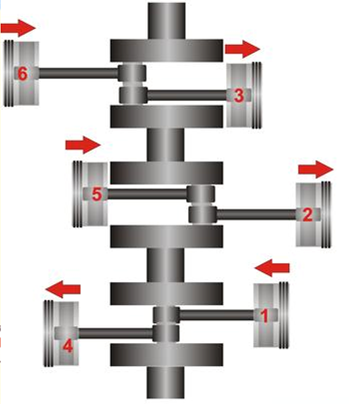

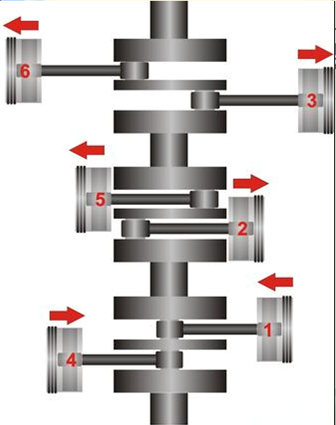

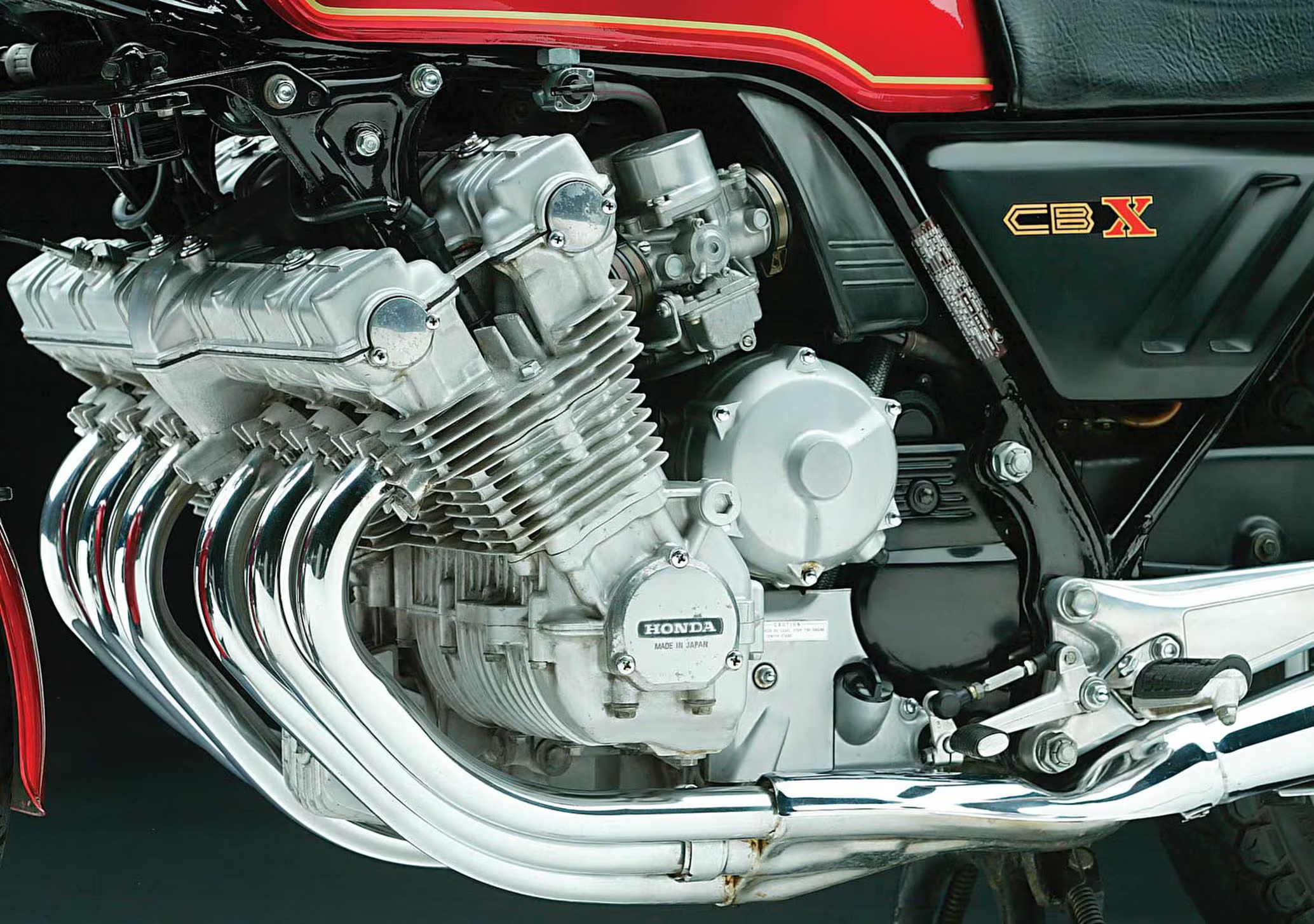

E. Common Engine Configurations

Four-stroke engines can be arranged in various configurations, which significantly influence their performance and applicability. Common configurations include inline, V, W, and boxer (opposite) engines. Inline engines have a simple structure and are suitable for smaller displacements; V engines are often used for high-performance models, providing greater power. The W engine combines the advantages of the V engine with greater combustion efficiency (although rare in motorcycles). Boxer engines are prized for their balanced performance and compact size.

1. Structural Characteristics of the V Engine

The V-engine design concept involves dividing all the cylinders into two groups and arranging them in two rows at an angle to each other, forming two inclined planes. Viewed from the side, the cylinders form a V-shaped configuration, hence the name. This design not only follows aerodynamic principles, but also effectively reduces the overall height and length of the engine, allowing for a lower engine hood and thus freeing up more cabin space. Furthermore, the angle between the cylinder banks helps balance engine vibrations.

However, the V-engine also has some disadvantages. Because it requires two cylinder heads, its structure is more complex than other engine types. Although its height is reduced, its width is increased, limiting the space on the sides of the engine and making it difficult to install other components.

2. Structural Characteristics of the W Engine

The W engine can be seen as a variant of the V engine. Its distinctive feature is that the cylinders on each bank of the V are slightly staggered. This design increases the engine's complexity but further optimizes space utilization, effectively controlling both height and width. However, it's important to note that, due to this unique structure, the W engine is rarely used in motorcycles.

3. Boxer Engine (Horizontally Opposed)

The unique feature of the boxer engine is that its pistons move horizontally toward each other. This design partially compensates for primary vibrations, making the engine run smoother. Furthermore, the angle of movement of the pistons provides good balance, reducing the need for counterweights on the crankshaft and therefore its weight. This advantage helps reduce the overall weight of the engine and improves responsiveness at high revs.

However, the boxer engine also has disadvantages. First, the manufacturing process is more complex and time-consuming, leading to higher production costs. Second, this configuration is best suited to rear- or all-wheel drive vehicles, limiting its application on other types of vehicles.

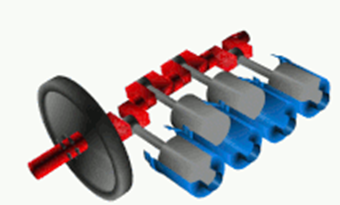

4. Inline Engine

The characteristic of the inline engine is that all the cylinders are arranged side by side in a single plane. This design makes the structure of the crankcase and crankshaft relatively simple. It typically uses a single cylinder head, reducing production costs. Furthermore, this engine offers high stability, excellent low-speed torque, and good fuel economy. Its compact size allows for wide application in many vehicles. However, the main disadvantage of the inline engine is that its specific power (power per displacement/liter) is generally lower than V or boxer configurations, especially with a high number of cylinders, due to its greater length.